Sandblasting Cleaning & Restoration

Reliable Commercial And Office Cleaning Services

Call Us: (647) 691-5314

Sandblasting: Cleaning And Restoration

When it comes to cleaning and restoring surfaces, sandblasting is a widely used and effective method. We will explore what sandblasting is, how it is used for cleaning, its advantages over other cleaning methods, the areas it can clean for businesses and properties, its safety considerations, and whether it is better to hire a professional company or do it yourself.

What is Sandblasting?

Sandblasting, also known as abrasive blasting, is a technique used to clean or prepare surfaces by forcibly propelling a stream of abrasive material against them. The abrasive material, which is typically sand, is propelled using compressed air or water pressure, creating a powerful force that can remove paint, rust, and other contaminants from various surfaces.

How is Sandblasting Used for Cleaning?

Sandblasting is a versatile cleaning method that can be used on a wide range of surfaces, including metal, concrete, wood, and brick. It is commonly used for tasks such as removing old paint or coatings, eliminating rust or corrosion, and preparing surfaces for painting or refinishing.

The process involves the following steps:

Surface Preparation: The area to be cleaned is carefully inspected and prepared for sandblasting. This may involve masking off certain areas to protect them from the abrasive material.

Abrasive Selection: The appropriate abrasive material is chosen based on the type of surface being cleaned and the desired outcome. Common abrasives include sand, crushed glass, aluminum oxide, and walnut shells.

Blasting: The abrasive material is propelled at high speed through a blasting nozzle using compressed air or water pressure. The operator directs the stream of abrasive material onto the surface, removing the unwanted contaminants.

Cleanup: After the sandblasting process is complete, the removed debris and abrasive material are carefully cleaned up and disposed of properly.

Advantages of Sandblasting

Sandblasting offers several advantages over other methods of cleaning and restoration:

Efficiency: Sandblasting is a highly efficient method that can quickly and effectively remove even the toughest contaminants from surfaces.

Versatility: It can be used on a wide range of surfaces, making it suitable for various cleaning and restoration projects.

Uniformity: Sandblasting provides a uniform and consistent finish, ensuring a clean and smooth surface for further treatment or coating.

Environmentally Friendly: Unlike some chemical cleaning methods, sandblasting does not involve the use of harmful chemicals, making it a more environmentally friendly option.

Areas Sandblasting Can Clean for Businesses and Properties

Sandblasting can be used to clean and restore surfaces in various areas, including:

Industrial Facilities: Sandblasting can effectively remove rust, corrosion, and old coatings from machinery, equipment, and structures in industrial settings.

Commercial Buildings: It can be used to clean and restore the exteriors of commercial buildings, removing dirt, grime, and old paint.

Residential Properties: Sandblasting can revitalize surfaces such as decks, fences, driveways, and brick walls, enhancing the overall appearance of a property.

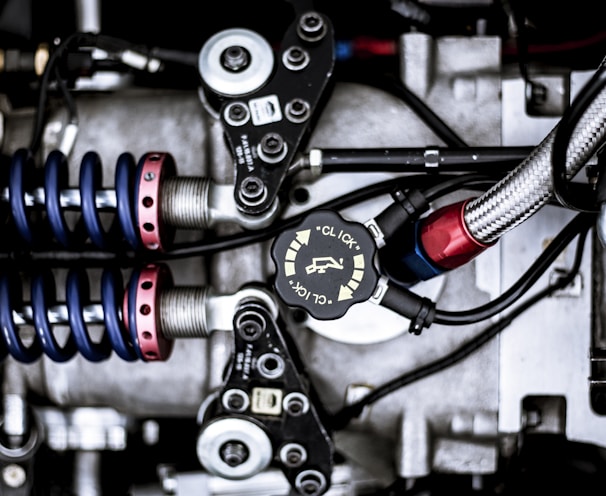

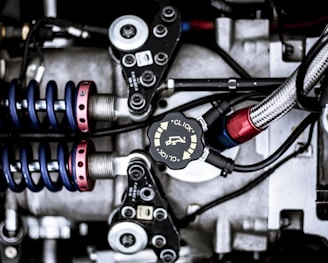

Automotive Industry: It is commonly used in the automotive industry to remove paint, rust, and other contaminants from vehicles and parts.

Is Sandblasting Safe and Effective?

When performed by trained professionals, sandblasting is a safe and effective cleaning method. However, it is important to take proper safety precautions to protect both the operators and the surrounding environment.

Some safety precautions to consider include:

Wearing protective clothing, including gloves, goggles, and respiratory masks, to prevent exposure to abrasive material and dust.

Ensuring proper ventilation in the work area to minimize the inhalation of dust and fumes.

Using appropriate containment measures to prevent the spread of debris and abrasive material.

Following proper disposal procedures for the removed debris and abrasive material.

DIY or Professional Sandblasting?

While it is possible for a business to purchase sandblasting equipment and learn the process, hiring a professional sandblasting company is often the better choice. Professional companies have the necessary expertise, experience, and equipment to ensure a safe and effective cleaning process.

When hiring a sandblasting company, consider the following factors:

Experience and Reputation: Look for a company with a proven track record and positive customer reviews.

Insurance and Licenses: Ensure that the company has the necessary insurance coverage and licenses to protect against any potential liabilities.

Equipment and Technology: Check if the company uses modern and well-maintained equipment to ensure efficient and effective cleaning.

Safety Measures: Inquire about the company's safety protocols and certifications to ensure they prioritize the well-being of their workers and the environment.

Cost and Timeline: Request quotes from multiple companies and compare their prices and estimated timelines to find the best fit for your budget and schedule.

In summary, sandblasting is a powerful and versatile cleaning method that can effectively remove contaminants from a wide range of surfaces. Whether it is used to clean industrial machinery, commercial buildings, or residential properties, sandblasting offers numerous advantages over other cleaning methods. While it is possible to do sandblasting yourself, hiring a professional company is often the safer and more efficient option. By considering the safety precautions and factors mentioned above, businesses and property managers can make an informed decision when hiring a sandblasting company.

Get in touch

Address

7030 Woodbine Ave Suite 500

Markham, ON L3R 6G2

Contacts

647-691-5314

info@officecleaningservicespro.net

Our Services

Clean Spaces, Happy Faces.

Areas We Serve